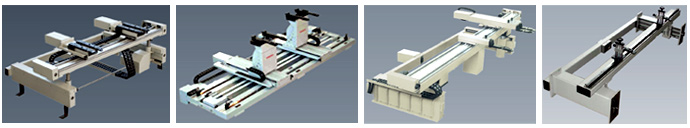

HYDRAULIC PRESS BRAKES

Standard Equipments

Hydraulic Press Brakes

. European (amada promecam) Type upper tool holder

. NC Controller

. Electrical panel with cooling system, designed to meet CE Standards and composed of automation and electrial equipments with Siemens brand

. Back gauge system driven ball screws on linear guides

. Original Bosch-Rexroth or Hoerbiger servo hydraulic system

.Hardened and grinded standard sectioned top and bottom tools (835 mm)

. Ergonomic, user friendly, moveable control panel carrying all buttons

. Back gauge fingers move along linear bearings with 0.01 tolerances

. Foot pedal conforming to CE regulation

. Front arms with T slot and mm/inch rulers.

HYDRAULIC PRESS BRAKES

Optional Equipments

Hydraulic Press Brakes

. Top tool holder with quick release system

. Sliding front arms with bearing rollers

. Special top and bottom tools

. Motorized Wila Anti-Deflection System which operates automatically

. With CNC unit according to tonnage applied

. Front light guard system

. Laser protection system for die area

. Laser angle measurement system

HYDRAULIC PRESS BRAKES

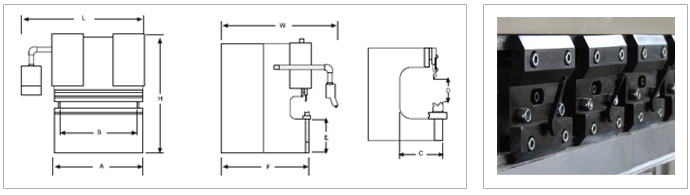

Backgauge Options

Hydraulic Press Brakes

(A) Backgauge system with X-axis:

. Travel on ballscrew spindles

. DC-motor driven

. Two micrometric stop - fingers with height and lateral adjustment

. Range: 650 mm

. Travel speed (max) : 330 mm\s

. Positioning precision: (+) (-) 0.03 mm

(B) Backgauge system with X-R axes:

. Travel on ballscrew spindles

. DC-motor driven

. Two micrometric stop - fingers with lateral adjustment

. Range, X-axis: 650 mm - R-axis: 160 mm

. Travel speed (max), X-axis: 350 mm\s - R-axis: 240 mm\s

. Positioning precision, X-axis: (+ (-) 0.03 mm - R-axis: (+) (-) 0.05 mm

(C) Additional backgauge axes for special applications:

. X1-X2 . R1-R2 . Z1-Z2

. Details of these special backgauge system are available on reguest.